How Does Concrete Patch Dry?

How Does Concrete Patch Dry?

A concrete patch serves as a reliable means of remedying repairs on a concrete surface. Whether the issue is a crack in the driveway or a wall repair, one must be well-informed about how the patch dries in order to achieve a long-lasting repair. Patching concrete involves a process of curing, which is the process of drying. Drying is achieved via chemical and physical changes that occur within the material. Now we will take a look at the stages that lead to the curing of a patch.

The Drying Stages of a Patch

Drying starts instantaneously when a patch is applied, where water in the mixture begins interacting with the cement. Hydration is a cement and water mixture and is known as a collection of chemical reactions in a closed system. Instead of simply evaporating, concrete is able to bond aggregates, which results in it achieving strength.

The process of hydration consists of the chemical reaction wherein calcium silicate hydrate (C-S-H) is formed. This compound is directly linked to the strength of the concrete patch. This reaction initiates on the surface and moves inward, which is the reason why the surface of the concrete patch is dry to touch prior to curing completely internally.

The Process of Concrete Patch Drying

Drying of a concrete patch can be classified into many important processes:

1. Setting Stage

Setting stage occurs the very moment the patch of concrete is applied. At this phase, the concrete patch begins its curing process as water in the mixture bonds with the cement. This phase occurs readily for the first few hours after application and is significantly impacted by temperature and humidity.

2. Hardening Stage

The hardening stage is where the patch progresses after the initial setting. The surface is now able to support some light contact, while the material continues to strengthen. At this phase, the patch may look as if it is dry, when in fact the hydration processes are still occurring internally. This stage can last anywhere from 24 to 48 hours.

3. The Curing Stage

This stage is the most important step of the four stages that drying processes have. It is the moment when the concrete patch attains its maximum strength and durability. Curing takes from a few days to over a week, depending on the patch size, type of concrete, and surrounding conditions. Even if the surface feels dry, the patch still requires moisture to ensure proper hydration during this time.

Factors That Impact Drying Time

These are some factors that impact patch drying time as well as curing time:

1. Patch Material Type

Specific concrete patching products differ from one another in term of their composition. Therefore, they all take different time to dry. For instance, quick-drying patches contain additives which allow for repairs to be accomplished in a matter of hours, whereas other patches will need at least 24-48 hours to dry and a week to cure fully.

2. Patch Thickness

This factor works the same way as the previous one, as the thicker the patch gets, the longer it takes to dry. Water also vaporizes and reacts quicker in smaller volumes, so thinner patches dry and cure quicker.

3. Temperature and Humidity

Temperature and humidity are critical to the entire drying method. Dry and warm weather will accelerate surface drying, but too much evaporation will cause curing problems. Meanwhile, cool or humid weather will reduce the evaporation rate and prolong the curing phase with the possibility of further increasing the repair’s strength.

4. Moisture Retention

Maintaining the appropriate level of moisture is essential for reinforcing the patch while it cures. If the surface dries too readily, it will crack and lose strength along with hydration.

Also Read: How Much Do Concrete Blocks Weigh?

Strategies for Succeeding Drying and Curing of Concrete Patch Works

For your concrete patch to dry and cure properly, here are some steps you should follow. First of all, it is very important to keep the area wet throughout the curing phase. You can lightly mist the concrete patch with water or cover it with damp burlap or plastic sheeting. This technique helps in hydration and retention of moisture. Protect the patch from the sun, wind, or heat in order to avoid rapid drying.

These elements can cause the surface to dry too quickly and result in cracks, shrinkage, or a weak finish. Indeed, for optimal results, remember the patch materials have specific drying and curing times, and it is always prudent to follow the manufacturer’s instructions. Process of repair will always be compromised if done in a hurry. Lastly, before steady loads are applied, adequate curing time needs to be allowed. While the patch may be dry on the surface, additional time is often required in order to for the patch to achieve maximum overall strength internally. Because of this, it is ideal to be thorough, as proper curing will help the patch to last longer and remain strong under various conditions and wear. Adopting the stated precautions guarantees a professional-quality repair that will endure weathering and daily use.

A Process of Hydration and Evaporation

Concrete patches dry via a process of hydration and evaporation which, alongside other methods, goes through various stages: setting and curing. Even though the surface of a patch looks dry in a few hours, internal curing takes days to complete for the patch to gain full strength. Types of patch materials, environmental conditions, and thickness of the application all influence drying times.

Adequate curing is paramount to achieving a successful and durable repair. If curing isn’t approached with the utmost care, there may be cracks, weak bonding, or undesirable uneven facades that compromise the repair’s structural integrity. Quick drying products may seem appealing, but these products help minimal while patching units. In such cases, adequate time should be provided for the patch to dry. To achieve the quickest set time, it is advised to follow the manufacturer’s instructions, utilize moisture before applying the patch for maximum effectiveness, and avoid extreme weathering conditions during the curing phases.

In the process of fixing a concrete surface such as a driveway or wall, it is important to ensure that a patch is cured correctly. Doing so will not only save you from maintenance efforts in the future, but it will also ensure that the concrete can withstand harsh environmental conditions. This process requires a lot of patience and attention to detail as it will determine the quality and level of durability in the surface.

How Much Do Concrete Blocks Weigh?

How Much Do Concrete Blocks Weigh?

Concrete blocks are one of the most basic construction materials, with applications for walls, foundations, and other types of structures. One of the common questions is: ‘How much do concrete blocks weigh?’ Depending on its size, its type, and the density of the material used to fabricate it, the weight of a concrete block varies. This article attempts to describe the conditions affecting the weight of concrete blocks and provides particular illustrations to help you understand the differences better.

Factors Influencing the Weight of Concrete Blocks

Block Size

The volume or size of concrete block determines its weight. Blocks that are larger will contain more material and therefore, will weigh more. The block that is most commonly used weighs 8 inches in height and width, and 16 inches in length (which is referred to as 8″x8″x16″). But there are other blocks, both smaller and larger than these, which will alter the weight.

Type of Block

Concrete blocks are classified into various types depending on their function and design:

• Hollow Blocks: These contain hollow cores or cavities which make them lighter without compromising on strength.

• Solid Blocks: These blocks are completely filled with concrete which increases the weight but makes these blocks more durable for structural purposes.

• Specialty Blocks: Like lintel blocks, corner blocks, and even decorative blocks often have their own designs and that affects their overall weight.

Concrete Weight

The relative weight of a block, is affected by the density of concrete mix which is used greatly. The blocks are made of different densities of concrete and categorized as:

• Lightweight Concrete Blocks: These types of blocks are made from expanded lightweight clay or shale and have a low overall weight.

• Medium-weight Concrete Blocks: These types of blocks use ordinary aggregates, but they are less dense than normal blocks.

• Normal Weight Concrete Blocks: These are the heaviest and are made from standard aggregates like sand or gravel.

Concrete Block Weights

1. 8”X8”X16” Concrete Block Weight

The 8″x8″x16″ blocks are the most frequently utilized size. Its weight changes depending on whether it is solid or hollow and the density of the concrete:

• Hollow Block: Weighs approximately 30-35 pounds or 13.6 to 15.9 kg.

• Solid Block: Weighs around 50-55 pounds or 22.7 to 24.9 kg.

2. Lightweight Concrete Block Weight

These blocks, typically employed for partition non-load-bearing walls, are significantly lighter:

• 8”x8”x16” Lightweight Hollow Block: About 20–25 pounds or 9 to 11.3 kg.

3. Other Normal Weight Block Flexibilities

• 4”x8”x16” Hollow Block: 15-20 pounds (6.8-9.1 kg)

• 12″x8″x16″ Hollow Block: 50-60 pounds (22.7-27.2 kg)

4. Blocks of Distinction

Blocks of specialty design, including those that are like lintels in shape, as well as ornamental blocks, have bulk variation due to them. Specialty blocks typically range between twenty to sixty pounds in weight based on size and function.

Importance of The Weight of block and its material

There is a multitude of motives for why it is essential to understand how much concrete block weighs.

Movement and Distribution

The required tools to move concrete blocks vary with their weight. Most construction-grade blocks are mobile manually. Heavier blocks, however, will require cranes or forklifts for relocation.

Building Settings

The block’s mass impacts the load bearing capacity of the block. Heavier blocks are suited for structural walls and non-load bearing walls are better off with the lighter blocks.

Financial Planning

Weight is also a factor for estimating costs of shipping concrete blocks, particularly in bulk purchases. Blocks that are heavier will add more costs in labor, additional equipment, and overall expenses.

How to Handle Heavy Concrete Blocks Safely

The moving of heavy solid concrete blocks is a difficult task requiring intensive labor. In order to handle it in an efficient and safe manner, it is important to follow certain procedures. As a primary step, always use back avoidance lifting techniques to reduce the risk of injuries or long-term strain by raising the block with the legs. If the entire weight of the block proves to be burdensome, lift it with a partner in order to reduce the exertion of physical effort.

For a large number of blocks, or larger projects, tools like forklifts, hand trucks, or block carts can be used in order to lift the blocks off the ground and transport them without impact to safety. The right gear should be worn as well since gloves, steel toe boots, and back supports can assist with preventing cuts or impacts from dropped blocks. Finally, organize the storage space such that the blocks are easily accessible for use and kept in a dry environment so as to prevent moisture absorption that may compromise structural integrity. Doing so minimizes wasted time and increases productivity at the work site.

The weight of concrete blocks bottlenecks around their size and level. The standard 8” x 8” x 16” hollow block weighs approximately 30-35 pounds while solid blocks of same size are around 50-55 pounds. There are lightweight blocks meant for easier handling which weigh around 20-25 pounds. However, larger blocks like the 12” x 8” x 16” blocks can be hollow or solid and their weight can range from 50-60 pounds.

Smaller Concrete Blocks

Smaller blocks like the 4” x 8” x 16” are significantly lighter and weigh around 15-20 pounds. Having the understanding of the weight of concrete blocks is vital while estimating costs and assuring safe handling. For instance, in bulk ordering of blocks with higher weight, heavy machines like pallet jacks are required for transportation. The weight of blocks directly impacts the amount of labor required as well. Heavier blocks will consume more manpower or even advanced lifting techniques. With large scale projects, having knowledge of the combined weight will also help when estimating the amount of storage space required at the site.

Efficiently and safely completing your project, whether it’s building a retaining wall, putting a foundation on a home, or even crafting a decorative feature, requires understanding the weight of the materials you will use. This can help in minimizing unforeseen complications.

You may also love to read this: How Many Bags of Concrete on a Pallet?

How Many Bags of Concrete on a Pallet?

How Many Bags of Concrete on a Pallet?

This article is about “How Many Bags of Concrete on a Pallet”. The primary decision for concrete projects revolves around determining exact material requirements. Buyers who get concrete in bagged form often ask how many bags make up one pallet. A clear understanding of pallet concrete quantity helps users plan their budget as well as handle storage together with transport requirements. This guide provides insight about concrete pallet loading practices including typical pallet contents and purchasing considerations and bulk movement strategies.

Standard Number of Bags of Concrete on a Pallet

40-Pound Bags

80 total bags of concrete weighing 40 pounds should fit optimally on one pallet. Pallet weight constraints do not restrict total capability because the lightweight construction of these storage containers enables greater bag numbers per stack.

50-Pound Bags

50-pound cement bags typically appear on pallets distributed with 64 packages each. The smaller packaging results in fewer items per pallet than bags of 40 pounds due to increased weight but maintains optimal pallet efficiency.

60-Pound Bags

Storage operators typically arrange 60-pound concrete bags in pallets with 56 bags per layout. Project developers choose this weight because it provides adequate mobility and space capacity while meeting both building requirements.

80-Pound Bags

To make a plastic concrete bag pallet each operator handles forty-two 80-pound heavy bags which are the major available weight category. Heavy concrete bags weigh much more than standard building materials do which means these packages need to be spaced further apart when grouped on shipping pallets.

Why Does the Pallet Weight Limit Matter?

A maximum weight specification exists for pallets to ensure both safe handling along with transport operations. Traditionally used pallets have weight capacities ranging from 3,000 to 3,500 pounds. Taking care because anything beyond the weight capacity will make the pallet unstable and create problems when operating forklifts or pallet jacks. To guarantee safe operations during transportation manufacturers determine pallet bag distribution by evaluating both weight and size measurements from the product dimensions.

How to Calculate Total Volume and Coverage

It is useful to know the bag count per pallet but equally essential to determine the materials needed for your project. A good starting point is figuring out exactly how much concrete you need. The measurement units for concrete projects usually consist of cubic feet or cubic yards. A standard formula for calculating volume is:

Volume = Length × Width × Depth (in feet)

The necessary number of bags becomes calculable once you know the cubic feet value and utilize the recorded yield measurements from each bag. Usually, 0.30 cubic feet of concrete can be obtained from one bag that weighs 40 pounds. You can get about 0.45 cubic feet from a single 60-pound bag. One 80-pound concrete bag generates 0.60 cubic feet of usable material. How many bags you need by referring to the yield of each bag. For example:

- A 40-pound bag yields approximately 0.30 cubic feet of concrete.

- A 60-pound bag yields around 0.45 cubic feet.

- An 80-pound bag yields approximately 0.60 cubic feet.

To determine the number of bags needed simply divide your total cubic-foot measurement by each bag’s yield availability. Start by dividing your total volume by the bag yield for each bag before dividing the result by the number of bags per pallet to estimate required pallet quantity.

How Many Pallets Should You Order?

Projects that need substantial concrete volumes yield lower expenses when you place bulk pallet orders compared to bag-by-bag purchases. Pallet bulk purchases allow you to save money by giving discounts while letting you stock up on enough material. A single 80-pound bag produces 0.60 cubic feet. To determine the required number of bags multiply 27 by the inverse of 0.60 giving 45 bags needed. To meet your project requirements you will need at least two pallets because each pallet contains 42 bags.t-effective and efficient than purchasing individual bags. Bulk purchases often come with discounts, and buying by the pallet ensures you’ll have enough material on hand. Here’s an example:

If you need 1 cubic yard of concrete (27 cubic feet) and plan to use 80-pound bags:

• Each 80-pound bag yields 0.60 cubic feet.

• Divide 27 by 0.60 to get 45 bags needed.

• Since there are 42 bags per pallet, you’ll need at least 2 pallets to complete your project.

If you work on small projects, you do not need entire pallets yet understanding the bag quantity on pallets lets you decide between bulk or single purchases.

Factors That Can Affect Pallet Quantities

Several factors can influence the number of concrete bags on a pallet, including:

- Manufacturer Standards: Manufacturers from various brands choose to present their products through diverse packaging methods that leads to slight changes in pallet container capacities.

- Bag Dimensions: Specialty mix types along with irregular bag measurements determine the maximum pallet density of concrete bags.

- Regional Variations: Changes to pallet methods could occur when local suppliers need to meet transportation or storage conditions.

Tips for Storing and Transporting Pallets of Concrete

Efficient storage and transportation methods must be used to protect both the quality of concrete products and people’s safety during the handling of multiple concrete bags. Here are some tips to keep in mind:

- The sensitivity of concrete bags to moisture exists because cement inside starts to hydrate when it meets water. Storage pallets must remain in dry enclosed spaces on raised platforms that keep them away from soil moisture.

- To safeguard pallets against weather elements, use a heavy-duty tarp when they are outside.

- The transport of concrete pallets needs special equipment including forklifts, pallet jacks and trucks equipped with liftgates to perform movement. Before movement take steps to keep the pallet from tipping or shifting off course.

- Before inserting bags into a concrete delivery system review the bag condition to confirm they haven’t incurred damage that might affect their contents. Effects on concrete mix can result when moisture breaches reduced concrete bags through their damaged surfaces.

Why Knowing Pallet Quantities Matters

The number of concrete bags which occupy a pallet serves multiple significant purposes in construction. The knowledge allows you to prepare an accurate budget because you can estimate quantities precisely. The determination of pallet quantities enables you to organize logistics storage alongside delivery shipment arrangements to allocate necessary storage areas and handling equipment. Additionally, pallet quantity knowledge simplifies interactions with suppliers and contractors through better communication so you receive your materials without delay during the ordering stage.

So, How Many Bags of Concrete on a Pallet? Standard bag configurations for concrete measure up to 42 80-pound bags across one pallet and 80 40-pound bags. You need this information to organize your project and determine costs while planning how to handle both storage areas and delivery logistics. The effective management of materials in building projects depends on your ability to comprehend pallet quantities no matter what size your project happens to be. Your success in the project depends on your careful calculations of what you need backed by supplier verification and prep for receiving deliveries.

You May Love to Read: Can You Pour Concrete in the Rain?

Can You Pour Concrete in the Rain?

Can You Pour Concrete in the Rain?

Concrete works best if done under right temperature, weather conditions, and time. One of the most common questions within the industry is, “Can you pour concrete in the rain?” The answer, yes. But there are a number of challenges to consider that range from complicated to strategic to avoid risks during pouring. If there is no preparation taken prior to pouring, rain has the potential to undermine the quality, strength, and esthetics of the concrete.

The Impact of Rain on Concrete During and After a Pour

It is critical to assess how rain will affect concrete if decided a pour needs to go forward. During a pour, newly placed concrete actively hydrates. Hydration is the process where cement and water are mixed to create a viable concrete structure. If there is rainwater, it can severely dilute the mixture and ultimately affect the water-to-cement ratio leading to the concrete being too weak.

Successfully Pouring Concrete During Rain

Make sure the site in question is ready to be poured onto, meaning the soil is evenly compacted and forms are set in place. Also, while not pouring, make sure to cover the area with tarps or plastic undergoing rainfall. Moreover, these should be removed just prior to pouring in order to prevent bridge-like structures blocking rain from getting into the site.

When pouring, remember to choose a concrete mix that is high-strength and resilient against precipitation. It is advisable to select a low-slump concrete mix which contains the minimum amount water. This type is less prone to being washed away by precipitation.

Most importantly after pouring the new slab, remember to not expose it to rainfall directly. It is advisable to cover the slab and edges with plastic sheets or waterproof tarpaulins to eliminate pitting and erosion.

Challenges of Pouring Concrete in the Rain.

A concrete pour during the rainy weather has numerous issues that can compromise the construction processes. A major one is the loss of strength. Rainwater weakens the concrete’s components by reducing the cement to aggregate ratio. The resulting mixture leads to lower compressive strength that makes the structure more prone to heavy impacts and cracking.

Another major challenge is surface damage. Rain can leach out any remaining micro-sized cement particles left on the slab’s surface resulting in a coarse texture. This surface appearance negatively impacts the slabs’ overall durability by making it more prone to abrasion in the future. In the event that troweling or stamping finishing work is to be conducted in the rain, it is more than likely that poor quality results will be produced.

Timing poses another key concern. Rain falling immediately after or during the setting period can interfere with the setting procedure, placing the slab in danger of water damage. However, if the concrete has cured sufficiently, then rain will cause minimal damage. These challenges must be dealt with in a way that is appropriate for the situation at hand, which means knowing when to put the brakes on and when to get going.

Pouring Concrete in the Rain: Why Is It Essential?

Even with these challenges, or especially with these challenges, pouring concrete during the rain may be the only option in some rare instances. Fulfilling a timeline on a concrete project, unexpected weather conditions, or logistical constraints make proceeding with a pour in less-than-ideal conditions easily necessary. In these situations, the proper steps can be taken in such a manner that the harm from rain will be reduced substantially and help achieve the project goals.

The moisture and cooler temperatures can actually help in the curing process, so one can do concrete pouring during the rains. High temperatures and direct sunlight, on the other hand, will definitely lead to the surface of the concrete drying out too quickly which results in cracks showing up along with a decreased structural integrity.

Pouring Concrete in the Rain Alternatives

Should the argument against pouring concrete during the rains be stronger than the one for, one can always use a different method to handle the pour. Always resort to putting off the pour till the periods of dry weather set in as this is the most optimal shift and approach. However, this is sometimes not possible due to other deeper constraints.

It is also possible to construct a temporary shelter on the pour site. Tents, canopies, and even framed tarps can be used as effective shields against rain while allowing the work to be completed. These structures should be strong enough to resist movement during windy conditions and should be well anchored. These types of shelter might require additional resources and time, but the pay-off will be beneficial in achieving the desired quality of the concrete.

Most Important Factors for Achieving Desired Results

It is more than imperative that when contemplating the pouring of concrete in rainy conditions, there needs to be a clear assessment of the control, which needs to be aligned with stage management. Start by checking the intensity, timing, and duration of rainfall. Light rainfall which occurs after the concrete pour is far more manageable, but if there is a cataclysmic rainfall during the early stages of the pour, then the entire pour could be at risk. Be sure to cover the entire base and the slab with protective materials, alongside some form of drainage as excess water can be damaging to the site.

Can you pour concrete in the rain? The simple answer is yes, although it poses challenges that should be planned and managed. Rain can reduce the strength of concrete, ruin its surface, and hinder the curing stage. However, with the right precautions and preparation, concrete can be poured in wet conditions. If you keep track of the weather and make use of proper materials while shielding the slab, you can achieve long lasting and durable results even with the rain. If the project is too large or too intricate, it is best to deal with an expert who can provide assurance and guarantee the quality of work done.

Also Read: Can You Poly Jack Concrete Yourself?

Can You Poly Jack Concrete Yourself?

Can You Poly Jack Concrete Yourself?

Concrete leveling can seem like a daunting task, especially when your driveway, patio, or walkway starts looking uneven. However, there are modern methods like Poly jacking that uses expanding polyurethane foam to lift sunken slabs. But many may wonder, is poly jacking a DIY friendly fix, or is it better suited for professionals? In this article ‘can you poly jack concrete yourself’, we will provide a step-by-step breakdown of the details regarding DIY poly jacking.

What is Poly Jacking?

Poly jacking is a method used to raise and even out a concrete surface that has sunk, and it is short for polyurethane foam jacking. This process includes pumping foam beneath the slab where it expands and fills empty spaces in the soil, which helps lift the slab and support the structure.

In ‘Can you poly jack concrete yourself’ the type of foam in use is high-density polyurethane foam that can withstand heavy weights and is also resistant to moisture and deterioration. The foam, once it has expanded and hardened, becomes a firm base for your concrete slab.

How Does Poly Jacking Work?

The poly jacking process includes four significant steps:

- Drilling: Using small bits, holes are created on the affected concrete so that foam can be injected into the concrete.

- Injection of Foam: Foam is injected through the drilled holes, where it expands and fills the empty spaces in the soil.

- Elevation and Leveling: The expanding foam pushes the concrete to its original position.

- Sealing off the holes: Covers are applied to the drilled holes making the surface smooth.

Benefits of Poly Jacking Over Other Methods

The advantages that poly jacking offers has led to its increased usage:

- Most tasks can be finished in a few hours.

- The procedure uses less and smaller cavities as compared to mud jacking.

- Polyurethane foam is resistant to water and will not break down with time.

- Some foams are produced from reused substances.

Reasons for Concrete Leveling

Common Causes of Uneven Concrete

There are multiple causes for Concrete settling;

Soil Erosion

The water undermines the slab, forming voids and resulting in sinks.

Insufficient Compaction

Inadequate pre-concrete compaction can cause uneven settling.

Weather Changes

Expansion and contraction cycles of the soil due to freeze and thaw can result in ground instabilities.

Heavy Loads

Sunken driveways or patios supporting heavy elements like vehicles or furniture.

Signs Your Concrete Needs Leveling

In ‘Can you poly jack concrete yourself’ some fundamental signals and indicators warrant your attention as follows:

• Hairline fissures in the concrete.

• Puddles in specific locations.

• Portions of the slab are sunken relative to other parts.

• Slopes that pose a danger of tripping on uneven surfaces.

DIY Poly Jacking vs. Hiring a Professional

Can You Do Poly Jacking at Home?

Indeed, if one is skilled with tools and is meticulous with directions, it is quite feasible to poly jack concrete by oneself. Polystyrene injection, and enhancement tools, along with instructions on how to use them, come in DIY kits. However, due to the high level of detail and accuracy needed to complete the job, it is not meant for just anyone.

Pros and Cons of DIY Poly Jacking

Pros:

• Cost-Effectiveness: Here, you expend less in comparison to professional assistance.

• Convenience: Work is rather done at one’s leisure.

• Satisfaction: Accomplishing a task alone is very fulfilling.

Cons:

• Equipment Cost: The cost of purchasing or leasing the required equipment can be hefty at first.

• Learning Curve: Errors can give rise to preventable damages or unsatisfactory outcomes.

• Time-Consuming: It can be longer than anticipated if no prior knowledge is possessed.

When to Call in the Professionals

A good rigid sidewalk repair company should have the latest technology to get the work done fast as well as properly. Thus, a little brain exercise in the area will help to know who is best for the task.

Tools and Materials Needed for DIY Poly Jacking

Essential Equipment for Poly Jacking

This is a comprehensive listing of hardware that one will require for a DIY task:

- Rotary hammer Adjustable drill with a 5/8-inch drill bit.

- Self-leveling polyurethane foam injection kit.

- Personal protective equipment Gloves and safety goggles.

- A measuring equipment like a level or a laser.

Types of Polyurethane Foam

It is worth mentioning that not every foam is beneficial for lifting concrete or oak floor. Use a specially made type – high-density polyurethane foam suitable for structural lifting. This foam’s expansion rate is very high, and its curing time is in minutes – establishing a solid base structure.

Step-by-Step Guide to Poly Jacking Concrete Yourself

Preparing the Surface

1. Remove debris and other loose materials from the surface to ensure that the foam sticks appropriately. This procedure makes sure that the slab lifts uniformly.

2. Depending on the dimensions of the slab, placement should be done at 2–4-foot intervals. Construct a plan for your injection sites.

Drilling Holes in the Concrete

• A 5/8-inch drill hole must be made using a rotary hammer drill.

• Excavate the slab until you reach the soil underneath. Make sure the distance between the holes is adequate to allow for even distribution of foam.

Injecting the Polyurethane Foam

1. Fix the injection gun to the foam container.

2. Place the nozzle inside the drilled gap and dynamically use the foam injector.

3. Pay attention to the hoisting procedure. Use a level to supervise the slab’s position and reposition the lift accordingly.

Monitoring and Adjusting the Level

• Work at a relaxed pace to prevent lifting too much material and to avoid developing low or high spots.

• Go through the above procedure for every hole after each foam has fully expanded before moving to the next.

Finishing Touches and Cleanup

• Adding some patching concrete and smoothing it out is critical before one can close the butt jointing and clean all excesses.

• When foam cures, it’s quite challenging to take off, so make sure to wash all equipment right away after using them.

Safety Precautions for DIY Poly Jacking

Personal Protective Equipment (PPE)

To precaution against dust and foam fumes, apply a mask, protective goggles, and gloves. Since polyurethane foam expands very quickly, be cautious when using it.

Handling Polyurethane Safely

• Skin contact with foam should be avoided as it is quite sticky and and may cause irritation.

• Use the product within the fume cupboard to avoid inhalation.

Preventing Damage to Surrounding Areas

• Use protective sheets on adjacent areas to avoid them being stained by unintentional spills.

• Apply low expansion foam to ensure it does not leak into areas which are not desired.

Common Mistakes to Avoid

Excessive Foam Injection

This can raise the slab excessively resulting in raised surfaces.

Holes Not Centralized

Evenly spaced holes are necessary to prevent inconsistent raising.

Hurrying the Task

More time is needed to achieve a flat, even surface.

Troubleshooting Issues During the Process

• Should the foam fail to fully expand, make sure there isn’t anything blocking the nozzle.

• Pay close attention to the slab, and cease injecting if you come across cracks or any other problems.

Understanding the Limits of DIY

DIY poly jacking is most ideal for small scale projects. Efforts involving bigger or more complicated tasks would be better managed with the assistance of professionals. Achieving levelling for sunken concrete with the help of poly jack is quite the theoretically practical approach. Moreover, it is also achievable at a personal level if you possess the right set of tools and equipment.

However, the procedure requires polyurethane foam to be understood in depth greatly. For ordinary constructional needs, doing it yourself can be beneficial, but for more sophisticated constructions, it is better to bring in professional aid. From this article ‘can you poly jack concrete yourself’ you can learn a lot of new things about construction.

White Oak Flooring Wide Plank Designs

White Oak Flooring Wide Plank Designs

White oak is an example of the best style of flooring. There are various sizes of white oak plank designs available, allowing you to choose what fits your space. However, one size that has become the most used commercially and retail is the white oak flooring with its wide plank design. The broad size has elevated many spaces from looking cheap to instant high-quality. Wherever you choose to lay them, there are a few things everyone should know. In this small read, we discuss the answer to the question- What You Should Know About White Oak Flooring Wide Plank Designs?

Why Does the Majority Want White Oak Flooring Wide Plank Designs?

Are you curious to know why more and more people are going wide white oak planks for their homes, shops, buildings, and office areas? White oak flooring wide plank designs are on every person’s Wishlist, and there is a feast of reasons behind that. Let’s uncover everything you should know about the beautiful white oak wide plank flooring designs.

1) It Makes the Space Bigger: The foremost reason is the space looks expansive. When smaller planks are installed, it makes the room look congested even if the surface has vast measurements, which is due to the number of white oak planks it takes to make the flooring. With wide size, fewer planks are used, opening up more space. For example, a kitchen is a place that needs to look bigger. Installing wide white oak planks there will broaden the space’s feel, presenting a better area for more than two people to stand and work.

2) They have Lastingness Quality: Lastingness is what every customer wants in their flooring, and if there is one thing you should know regarding white oak planks is about how stable they are. The wide planks are made of natural white oak wood harvested with many steps of carefulness. Furthermore, the expansive size of the planks makes maintenance and cleanliness easier. And they are known to bear hefty furniture and objects without breaking or tearing.

3) The Space Look Expensive: Elegance and chicness are what flooring is responsible for. If the flooring is cheap, the whole space and furniture will look low-grade, which is not the direction one is trying to achieve. White oak flooring wide planks have the potential in to make the area look expensive with its natural warm hue, sophistication, and smooth texture.

4) Makes the Room Captivating: If you notice, white oak planks have eye-catching designs, which is the eye-catching factor. With the planks being vast, the patterns are highlighted to a greater extent. The more apparent the patterns will be, the more the white oak flooring will have a visual that is appealing and shows the beauty of itself and the space.

5) They are Versatile: Did you know that white oak flooring wide planks can be installed in many places and not just the living room? They are versatile in their use, which can be seen in their use in kitchens, bathrooms, bedrooms, dining rooms, basements, offices, retail shops, etc.

6) Wood Stains: The wide oak plank designs can be available in different stains, such as warm tones, natural tones, brown hues, dark tones, beige colors, and custom colors. You can choose them depending on the amount of warmth you want in your space.

7) They are Eco-friendly: The last thing you should know about white oak floorboards is that they are eco-friendly. The wood is sturdy and long-lasting, which ensures no more white oak trees are being cut down.

Installing Wide White Oak Flooring Design

Installing vast white oak planks takes five to seven days. They are easy to install and can be done with the help of professionals, or you can try to bring out your hidden floor designer outside! The installation process includes cleaning the floor and laying the planks with the help of adhesive. In the end, finish the process by coating the flooring with matte or gloss for a sophisticated and polished look. For the white oak floor to be in its best quality, do not start touching up the space immediately; wait for at least 72 hours.

The Caring Methods of White Oak Wide Plank Flooring

There are many floors that are easy to care for. The wide plank flooring can be taken care of effortlessly, but there are some factors you should know to protect it. Here are the white wide oak plank design cleaning methods you should know about.

- Cleaning the floor every day is necessary. Missing one day can cause the dirt to be gathered at one corner of the floor, causing the beautiful wood to have a flaw.

- The life of the white oak planks is long-lasting, but at some point, they need refinishings. Refinishing will bring out the fading beauty, making the floor stunning again. However, refinishing as a caring method does not mean you need it every year or two. It will take at least ten years for the first refreshing touch to take place because of how high quality the white oak is.

- During the laying process, protective coats are applied to the planks to shield them from moisture. It is crucial to take care of these coatings. Make sure that every spill gets cleaned properly, and cover the coating with low-weight furniture or carpets.

- Refrain from mopping the floor with bleach as it can be harsh on the wood, so ensure to use wood-safe cleaners.

In conclusion, these are all the vital factors you should know about white oak flooring wide plank designs. For a new homeowner, retail shop owner, or someone looking to reconstruct their office, broad plank designs of white oak are the solution you should this modern and natural plank. Therefore, invest in broad white oak plank designs to enhance your place with warmth, coziness, elegance, long-term commitment, versatility, and sustainability. Expansive-size white oak plank designs are the decision you should make!

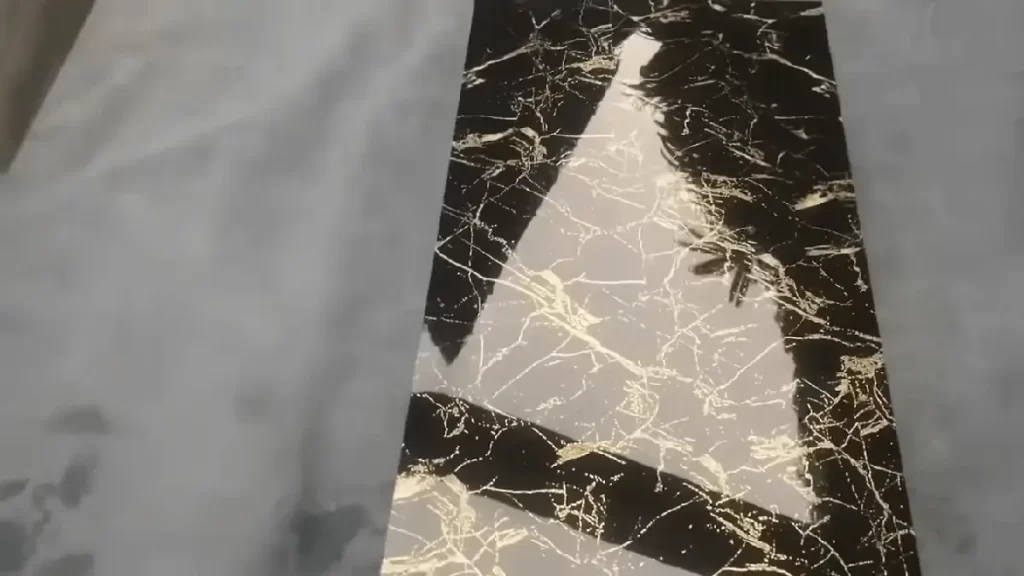

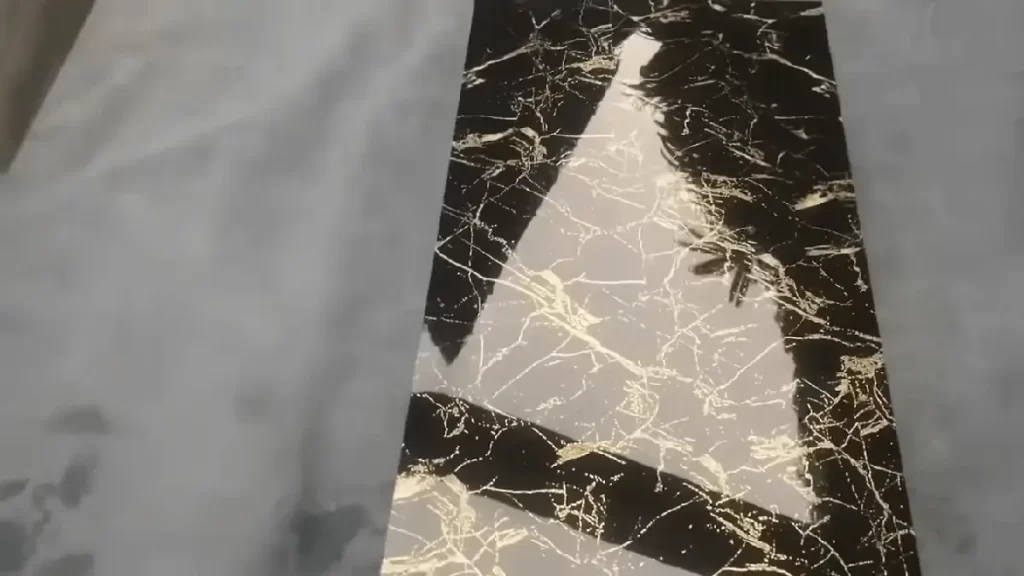

What Sets Thor Color Tiles Apart for Strength and Style?

What Sets Thor Color Tiles Apart for Strength and Style?

Every time a space is being designed or reconstructed, the first concern is what type of flooring will suit the place. The majority of people look for a foundation that is durable, reliable, aesthetically pleasing, and blends with the interior decor but fail to find it because not every flooring material has those features. Thor color tiles contain the four characteristics of what makes pleasing flooring and exterior. This foundation is eye-catching and expert in turning the place from nothing to offer to ravishing. The following will cover everything you need to know about what sets thor color tiles apart for strength and style. Let’s start reading!

What Are Thor Color Tiles?

Thor color tiles are mostly made from ceramic or porcelain to add uniqueness to your interior and exterior design. However, they can be customized in materials that customers prefer. These styles of tiles, compared with the standard tiles, have more variety in colors and designs, making them the customer favorite in the market.

List of Factor Setting Thor Colors Tile Apart

Choosing thor color tiles for the interior and exterior of your living or commercial space is the best decision. Even without knowing the facts, the tiles’ appearance speaks for itself and does not require much convenience. But to let you know what you are going to get, here is a list of factors about what sets thor color tiles apart for strength and style.

Factor One: Incredible Strength

Thor color tiles undergo a manufacturing process with the assistance of heavy and modern machinery, ensuring that the tiles are sturdy and durable. Their strength is so impressive that even after years of being installed, they will not chip, scratch, or have scuff marks caused by furniture or shoes. Ultimately, thor color tiles’ reliability became a factor making them better than others.

Factor Two: Stunning Fashion

Another factor setting the thor color tiles apart from traditional tiles is their stunning style. There is no other flooring that comes close to the versatility that these types of tiles have appearance-wise. The thor tiles have diversity in colors; some examples are neutral shades, pastel shades, bold colors, and earthy shades. The choice of hues available allows you to pick what compliments the space.

Factor Three: Suits All Settings

Tiles are used for many settings, but there is no guarantee they will suit there. What sets thor color tiles apart for strength and style is their potential to look flattering in a residential environment and a retail setting. Additionally, each setting will have a different mood created by these tiles, elevating the atmosphere and making it unique.

Factor Four: Environmentally Friendly

Many customers and contractors are refusing materials that cause harm to the environment. A better alternative is to employ sustainable thor color tile flooring. These tiles are created by using eco-friendly materials, and the manufacturing process produces less emissions.

Factor Five: Customization

Thor tiles allow customers to customize the tile, matching their needs. This customization feature can change the shape, color, and pattern of the tiles as per the demand of the clients. With thor color tiles, you will be walking on the styled flooring you hoped to see.

Factor Six: Effortless Cleaning

Thor color tiles function also includes ensuring they stay clean and refined. These tiles are non-porous, making them safe to be assembled in places where there is use of water, such as a bathroom, kitchen, and outdoor spaces. As there are chances for them to be dirty with stains or dampness when applied in shopping malls and homes with children, these tiles have been manufactured as easy-to-clean. You will not have to scrub on them; one sweep of the mop will clean everything that is blocking its vibrant visuals.

These factors show the diversity and functionality of thor tile foundation for interior and exterior, proving that they are not like the rest and will meet every demand of the customers.

Can Thor Color Tiles Be Trusted?

Thor color tiles have earned a good reputation for being the most used tiles for their benefits and luxury builds, making them different from other flooring. What makes these tiles trustworthy is their durability and resistance to factors that could damage other tile flooring. Moreover, these tiles are the most trusted and recommended flooring in the world of property design. Many contractors and interior designers would suggest thor color tiles for luxury. Therefore, that clearly explains that thor color tiles are the most trusted tiles for your space.

Are the Tiles Only Applied to the Home Interior?

Thor tiles bring versatility in their application with their stunning looks. That is another reason to add on what sets thor color tiles apart for strength and style. Whether you are a homeowner or a shop owner who needs elegant and bright flooring, these tiles are worth choosing. Here are some examples presented where these tile flooring can be applied.

- For homeowners, do not hold back in where you want them to be. They can even be installed outdoors!

- Get thor color tiles to create a warm and welcoming atmosphere at your retail or shopping space.

- They can be installed for creating polished flooring in office buildings.

- These tiles can be customized with patterns- a perfect opportunity to elevate the walls.

- Schools, classrooms, and healthcare facilities are other places where thor tile flooring works well.

So, are these tiles worth spending money on? The answer is that is yes. Thor color tiles come in radiant style, matte style, and minimal style, offering different functions and visuals for various preferences, making them a versatile flooring option. The foundation of your interior and exterior design will be robust and incapable of damage and soaking moisture that would turn the thor tiles into mold. In short, this tiling option is suitable and functional for every place and space and has many factors, stating they are what sets thor color tiles apart for strength and style. You may also like our post on sub-flooring over concrete.

Can You Install a Subfloor Over Concrete?

Can You Install a Subfloor Over Concrete?

Concrete is the most popular choice of material for flooring and has many advantages. But, with so many pros, there are also a considerable number of cons that make the owners worry about the foundation. However, there is nothing to be concerned about because there are different options available to install over concrete for better protection. When the concrete starts deteriorating, the first option that customers and contractors think about is what should be a better option. The famous choice is adding a subfloor over the concrete. Subfloors are known to enhance the floor by making them esthetic and comfortable. Before you decide, it is essential to know about subflooring. In this article, we will discuss questions like can you install a subfloor over concrete?

Meaning of a Subfloor

Subfloors are extra layers laid down structurally before the actual flooring is completed. These subfloors are installed for many reasons- to protect the flooring from getting damaged, and they can be applied on every type of foundation. Since it is not impossible to change flooring due to circumstances, choosing subfloors is an easy and affordable option to protect the flooring.

What Subfloors Can Be Used for Concrete?

Many subfloors can be installed over a foundation of concrete. Four different subfloors are most used by people and even construction contractors, which answers the question- can you install a subfloor over concrete? – with a yes. Have a look at them and pick your choice.

1. Dry Lay Subfloors: Dry lay subfloors have interlocking panels, which means they do not need any adhesives to install. This type of subfloor is mostly chosen due to it being layered for protection from dampness.

2. DriCore Subfloors: DiCore subfloors are an outstanding alternative if your concrete can not resist moisture. They come with layers of two different materials. The top layer is the Oriented Strand Board (OSB), and the bottom layer is made of polyethylene.

3. Plywood Subfloors: There are two kinds of plywood subfloors: raised and adhered. Raised plywood leaves a space for air circulation, and the adhered plywood is placed over concrete using tools.

4. Oriented Strand Board (OSB): OSB is the sturdiest subfloor option. They are designed from compressed wood strands that get arranged in a unique intersection pattern with a smooth surface.

Reasons Behind Placing Subfloors Over Concrete

While concrete rarely has any consequences, there are times when it can happen, and when that occurs, the only option is to add subfloors to it. One disadvantage of concrete is that it needs to be sealed properly, or else the moisture will find its way inside, damaging the surface. Subfloors are installed over them that act as a protection layer to prevent the concrete from deteriorating.

A home is comfortable when it is warm, and concrete is a material that blocks the heat unless it gets layered with subfloors. A subfloor installed over concrete keeps the place warm and cozy. Concrete can make the floor bumpy or uneven when setting different types of flooring, leading to poor presentation and low durability. That is what subfloors fix; they add elegance to the flooring and make it have high longevity rates. If the concrete is not giving its services, do not hesitate or wait to get subfloors. Ignoring the signs can lead to costly repairs. Therefore, do not ask the question can you install a subfloor over concrete repeatedly and have it placed to improve the comfort and quality of your floor.

Is Subflooring Cost-Effective?

Subflooring is a superior chance to improve the flooring, which also gives an elegant touch-up to the interior; the prices depend on the type of subfloor. The factors affecting the pricing include the type of subfloor and how they are installed. For example, the installation process of the dry lay subfloor includes making it water-resistant and underlayment of foam, positing the panels, and securing the perimeters. The cost will depend on the materials used and the dimensions of the concrete ground.

Additionally, if you assign professionals for help, it will affect the price, and if you do it yourself, that will have its own cost. However, installing subfloor layers over concrete will be cost-effective. What is more profitable is that they are done once, so you do not have to change the entire flooring, making it a long-term investment.

Why You Should Get Subfloors Over Concrete

Subfloor over concrete offers many benefits. Flooring needs to be comfortable, too, and concrete alone cannot provide that. Subfloors deliver comfort to the place with their cushioning, making the floor comfortable to walk and sit on. If concrete is not covered with subfloors, there can be privacy issues as your conversion could be heard by other people, especially in residential settings. Installation of a subfloor will block conversation and disturbing noises with its high-quality soundproofing abilities.

The most vital benefit of adding a subfloor is to prevent moisture from creating mold. Concrete is permeable, but subfloors are non-porous, which creates a layer of protection that blocks the way for water to reach the flooring.

Can It Protect Different Flooring?

Subfloors are a versatile option that offers a stable ground for all flooring types, from hardwood to tiles. It will protect each flooring with its high-quality services and make your floor gain strength, keeping it alive and new for years. So, are you still considering if you can install a subfloor over concrete?

In closing, the question, can you install a subfloor over concrete, has reached the conclusion that yes, you can install a subfloor over the cement. The signs of your flooring losing its quality should be enough to get subfloors to save a significant cost of getting a new floor. Protect your floor from moisture, add warmth and elegance, and let it keep its freshness unchanged with subfloors with an easy and reasonably priced solution. With all this information, it has become clear that subfloors can be installed over concrete- time to protect the flooring.

How to Smooth a Rough and Pitted Concrete Floor?

How to Smooth a Rough and Pitted Concrete Floor?

Concrete floors are not only for residential spaces but can also be used for various spaces. The flooring does not have a limited time, but over time can become rough or pitted due to different reasons. If your cement flooring is changing and losing its charm, then you should learn how to smooth a rough and pitted concrete floor. There are five steps that need to be followed to achieve an even surface for the flooring. In this article, we will expose all the steps. Continue reading to find out.

Five Ways to Smooth a Rough and Pitted Concrete Floor

Fixing concrete saves from unfortunate events, and if you are looking for simple steps on how to smooth a rough and pitted concrete floor, here are five actions you can take.

1. Floor Checking: The fixing can not be started until the floor is thoroughly checked. Floor checking is crucial to understand what type of roughness it is experiencing and working on it respectively. When you are inspecting the foundation, the damages can be seen in two ways- minor pits and extensive cracks.

2. All the Stuff Required: After checking the foundation and knowing the type of pits and roughness it has, pile the appropriate materials and tools required. The suitable possessions will ensure that the concrete floor has a smooth finish.

Floor checking and having the proper materials and tools are two steps that should be followed before the process starts.

3. The Surface: The surface needs to be prepared correctly so the finish of the rough and pitted concrete floor is flat and even.

- First, the floor should get cleaned with a broom or vacuum, and by using a cleaning substance, stains should get wiped off.

- Grind the surface with light touches to smoothen out the roughness and pitted areas on the concrete.

How will Grinding Help the Floor?

The grinding disc will flatten the surface by removing every imperfection. Furthermore, it will also clean the stains and dust that can not be removed by cleaning substances. The smoothened concrete will help in applying the mixture.

4. Spreading Mix: Apply the mix on the rough and pitted concrete floor by pouring and spreading it thinly using tools like a trowel. Leave it for two to four days. During this time, the compound will fill in the cracks and cover the roughness

5. Sealers: The last step to follow for how to smooth a rough and pitted concrete floor includes sealing the concrete floor surface. Whatever seal you choose should be applied evenly to ensure no area on the floor is left to seal.

Types of Sealers to Fix Rough and Pitted Concrete Foundation

Concrete sealers will protect the flooring to not encounter roughness or weariness. They also make the floor durable and revive its visuals. There are three types of sealers that are the most professional to use for finishing the surface.

- Polyurethane Sealers: Polyurethane is a thick sealer that closes the faulty parts of the concrete. There are two types of finish that this sealer can provide- glossy and matte.

- Acrylic Sealers: There are water-based and solvent-based acrylic sealers available. They are a thin substance, protecting from sun damage. Additionally, acrylic sealers are the most reasonable that can be found.

- Epoxy Sealers: Similar to polyurethane, epoxy sealers have a thick layer. The advantage of this sealer is its longevity and protection from stains and chemicals, keeping the concrete floor safe.

What is the Reason for Concrete Floors to Become Rough and Pitted?

Knowing how to smooth a rough and pitted concrete floor is vital for the best finish, but understanding the reasons behind the condition is just as crucial, which will help in taking care of the concrete floor.

- The common reason for a smooth concrete floor to turn rough and pitted is moisture. Water can find its way into the flooring, creating cracks and bumps.

- Wear and tear is a possible reason. Concrete floors are found everywhere. In industrial areas, heavy machinery can cause tearing, while in residential spaces, furniture moving leads to rough patches.

- Floor maintenance not done adequately or not done at all is a big reason why the concrete surface will be rough and pitted.

- In industries where chemicals spill onto the floor can cause the floor to weaken. It is essential to seal the mixture to prevent that.

The Material and Tools

A straightforward way to smoothen out the rough and pitted concrete floor is to have the materials and tools present.

There are four materials that are required in this method, which are

- Self-leveling concrete because it will repair the uneven surfaces even.

- Patch compound that will be used to fill and distribute on the cracks and pitted surfaces for a flat finish.

- The grinding materials are required materials to clean and polish the concrete floor.

- For protecting and ensuring the long life of the cement foundation, sealers are an essential material item.

The Important Tools

- A vacuum cleaner is necessary to clean the dust from the floor, or you can use a broom.

- A trowel to evenly apply the compound and concrete on the rough and pitted surface.

- A scraper to scrape out all the concrete tearing apart.

- Measuring tools to correctly estimate the mixture, ensuring it is of the proper consistency.

- If you are working in a closed space where the light does not enter, keep a torch or light equipment present.

It is clear now how to smooth a rough and pitted concrete floor. Flooring should get checked after a few years to see if there are any gaps or pitted spots that need to be filled. The plan is easy- check the floor, have all the tools and materials on-site, clean the surface, spread the mixtures, and seal it with your choice of sealer. By following that and taking care of the foundation, your concrete floor will be of high quality and regain the lost durability.

What is Concrete Float?

What is Concrete Float?

Everyone has seen a concrete float getting used at a construction or reconstruction site on the cement flooring. It is either used once or more than once and always on the flooring of the project. However, there are still a few who do not know what is concrete float. If you are one of them, take a few minutes to read this article to be educated on concrete float and how and why it is used.

Answering the Question

Concrete floats are a heard name, but what is a concrete float? A concrete float is a significant tool that has the purpose of helping the mixture spread evenly. When the fresh batch of concrete mixture gets poured on the surface, a float is put to use to distribute it uniformly all around. The mixture is laid down evenly and smoothens the surfaces, making the result consistent and appealing after drying. It is an easy tool to work with that homeowners use to fix the concrete flooring of their home, garage, or basement. It is a crucial tool for the quality of the flooring. Not using this on time leads to an unstable and uneven floor with cracks and moisture hidden inside.

Exploring Different Types of Concrete Floats

There is not one kind of float that can get purchased; you will find three different floats. The three concrete floats have distinct services for concrete projects. The diverse types of concrete floats for finishings are written below to help you select the most suitable one for your project.

1) Power Floats

Power floats have rotating blades, making them the best help for large-scale projects, such as industrial space or building sites. This float is time-effective as the blades reach father areas to smooth the immense concrete flooring in a brief time.

2) Bull Floats

Bull floats are ideal to cover large areas of concrete. These floats come with a handle, creating an easiness for sliding them around to polish and flatten the concrete foundation. Furthermore, they are an immense tool, making them excellent for extensive operations.

3) Hand Floats

Hand floats are made with three different materials- which are wood, magnesium, and aluminum. All get used for separate reasons- wooden floats for gaining a natural touch and magnesium and aluminum for an elegant and durable surface. Hand floats should get utilized if your concrete requires minor touch-ups rather than significant fixing.

Why are Concrete Floats Used?

We know what is concrete float, but why are they used? Concrete faces many issues when it is freshly poured, and if it is not fixed as soon as they are detected, the whole surface loses its aesthetic and durability. The most common issues a concrete floor comes into contact with are moisture and unevenness, losing the flooring strength and balance.

A foundation made of cement weakens due to moisture. Concrete float is used to remove the water on the fresh cement, which erases the possibility of cracks after it dries. During application, the mixtures can be spread more on one side than the other unconsciously, and concrete float fixes make the surface look uniform. Through that, every area of the concrete floor is solid and smooth with no bumps. The concrete mix has air bubbles that are hard to remove during the application, but the floats perfectly pop the air bubbles, making the surface stable.

Using Concrete Floats in Various Fields

Continuing the topic- what is concrete float? We will now discuss where are concrete floats used. Concrete floats benefit every field that requires its assistance.

- They are most used for residential projects for smoothing the finish of a concrete patio, driveway, or the floor of a garage. Additionally, minor cracks and pits can get fixed using concrete floats as it evenly lays the mixture on them, reshaping the surface. The flooring is durable and sturdy, ensuring it works for a long life.

- They provide their assistance in commercial operations, such as a building. Because the concrete portions have a larger size than the standard at commercial sites, bull or power floats are used that flatten the surface in quick rounds, making the foundation flawlessly consistent and balanced.

- Bumps and cracks on roads are an indication that the foundation needs to be reshaped by closing the cracks and making the pavement even. Concrete floats are crucial for that since they have the means of making the road safe for people.

- Damages are seen on sidewalks, making it dangerous for people to walk or stand. The concrete float comes in aid for improving sidewalks.

Instruction for Using Concrete Float

Get the smooth finishing for your concrete floor by following a few instructions. Here is how to use concrete float:

When to Use?

Start using the concrete float after the mixture has been spread in matching levels on the entire area.

The Condition of the Floor

Do not use the concrete float on a wet or completely dry foundation. The condition of the surface should be between damp and dry. If you wait for it to dry or start using the float when the floor is still moist, the result will not come out as expected.

Amount of Pressure

The concrete float should not be pressed so hard that it sinks into the fresh floor. Instead, sweep the machinery with gentle hands.

Repeating Time

Floating can get repeated if there are still pressing needs to get done. The repetition time depends on how smooth you want the surface to be.

Concrete float is used to even the surface during the construction. With this tool, when the flooring is dry, it will be smooth, aesthetically eye-catching, and durable. Furthermore, the stated machinery is diverse and can be used in small to large-scale projects. A concrete float is a vital key for the flooring that ensures the concrete flooring is stable and visually appealing. Therefore, always use concrete floating on the flooring. Hence, here we conclude the answer to what is concrete float.